Technical Service

scroll down

Technical Service

EOS/ESD Assessment

EMI Assessment

Training Programs

Technical Assessment Service compliance to ANSI/ESD S20.20 and IEC 61340-5-1 ESD Control Program or ultra-sensitive device handling beyond 100V CDM ESD level followed by ANSI/ESD SP17.1 Process Assessment document.

Semiconductor standards SEMI E-128, E-78, and E-43 have their own scope with CDM 100V included with automated handling equipment.

Assessment Scope Level 1.

Technical Assessment Service compliance to ANSI/ESD S20.20 and IEC 61340-5-1 ESD Control Program or ultra-sensitive device handling beyond 100V CDM ESD level followed by ANSI/ESD SP17.1 Process Assessment document.

Assessment Scope Level 2.

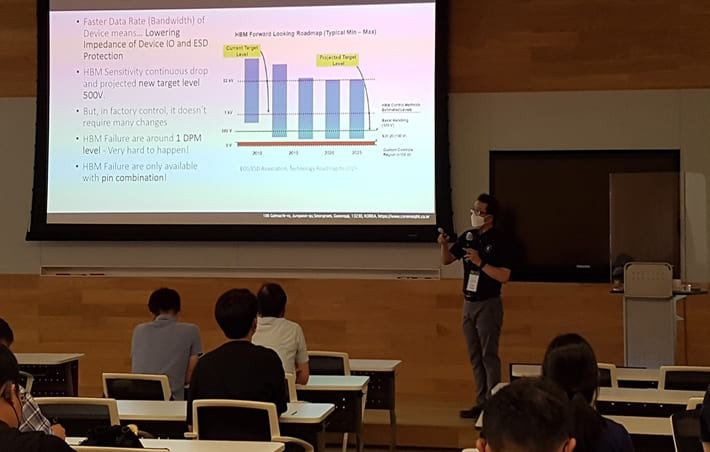

CDM 100V or lower than 50V. Ultra-sensitive fast device such as die-to-die interface ESD sensitivities are already much lower 30V or down to 5V. This process requires very detailed assessment step-by-step of processes. Core Insight has many yield improvement case studies and could solve various kinds of static related issues.

Technical Assessments

ANSI/ESD S20.20 Program Assessment Scope

- ESD Control Program Review

- Administrative and Technical Requirements Elements Suitability Review

- Product Qualification Suitability Review

- Compliance Verification Review

- Training Plan Review

- Process Assessment from Incoming to Final Packaging Process

Advanced Technical Process Assessment Scope

- Assessment Findings : Listing Major Impact Elements and Evaluation Technical Gaps,

- Major focuses are CDM/CBE ESD control gap findings on current production line compliance to CDM sensitivity level of devices in production

- ESD Event Detection and Risk Analysis will be the most critical measurement through the process.

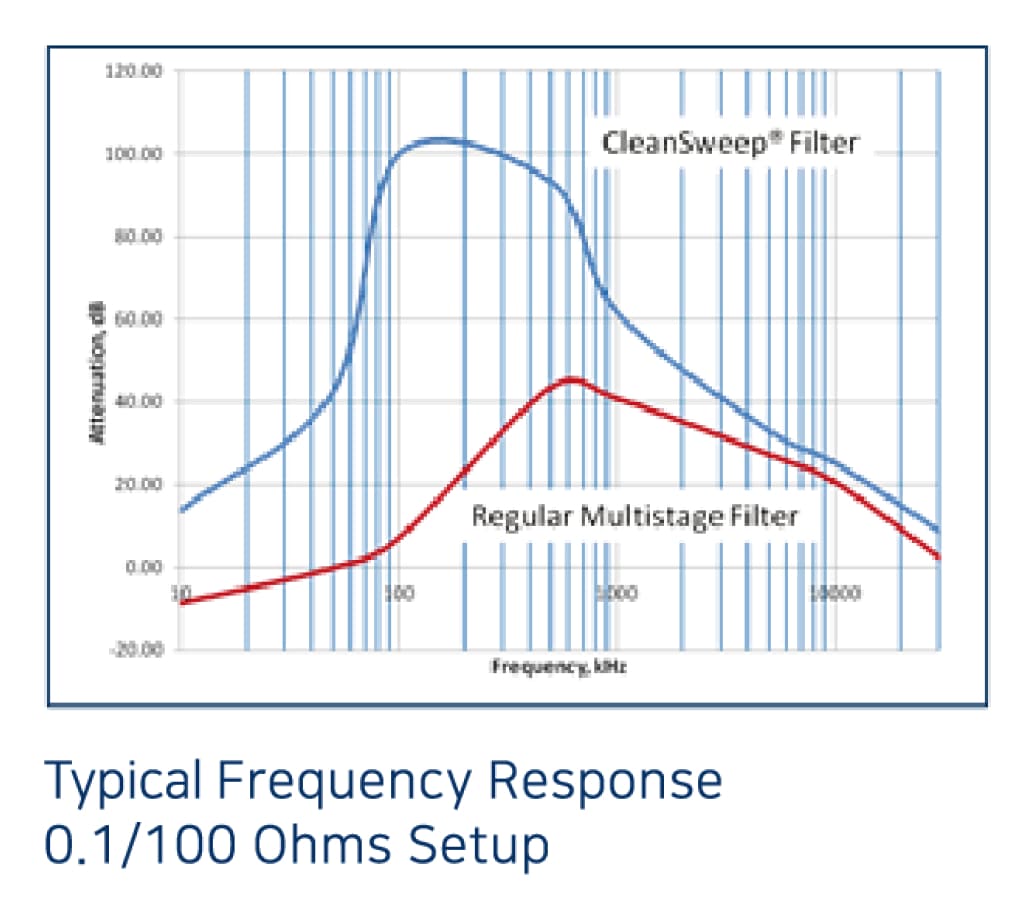

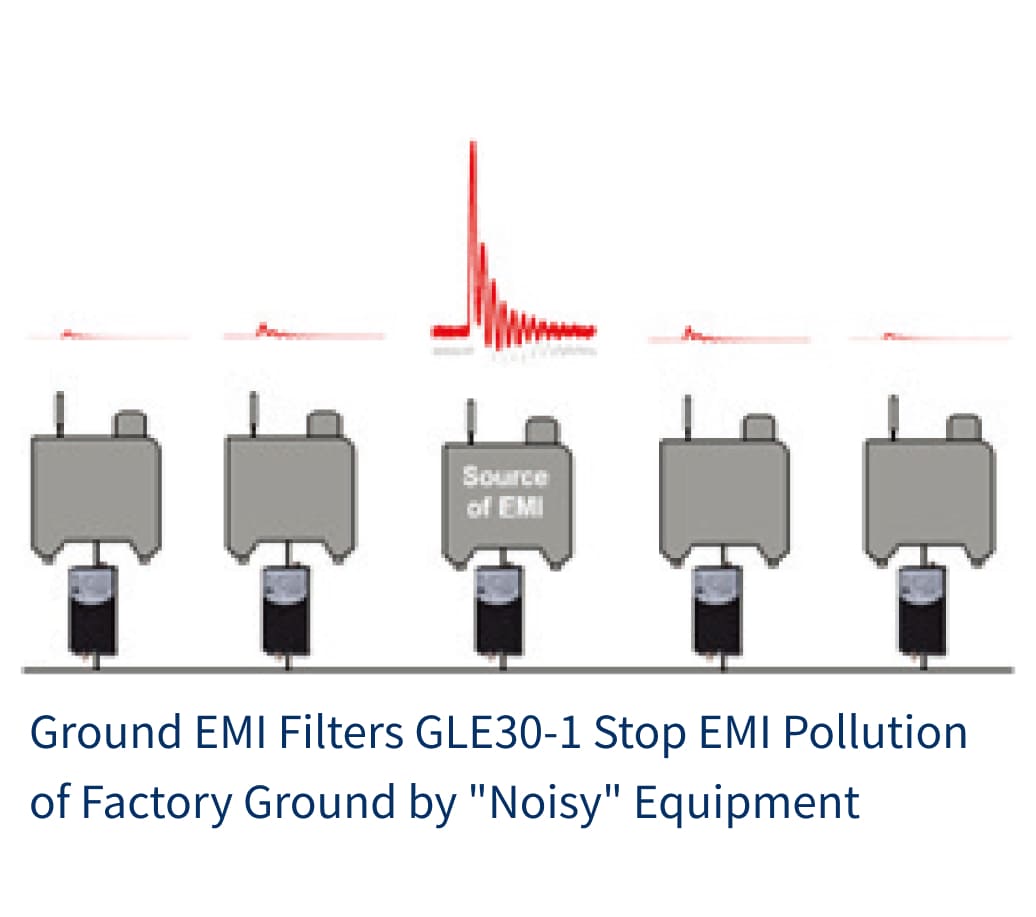

EMI Technical Assessment Service compliance to SEMI E176 EMI in Semiconductor Manufacturing Environment standard.

Assessment Scope

SEMI E176 EMI control guidance standards have their own scope as follows;

Category | Recommended Device Geometry Size Range | Radiated Emission | Conducted Emission | Ground EMI Current | |||||

Near Field | For Field | ||||||||

Peak | Continuous | Peak | Continuous | Peak | Continuous | Peak | |||

1 | ≥ 28.3 nm | 2 V/m | 1 V/m | 1 V/m | 0.3 V/m | 0.3 V/m | 90 dBμV | 31.6 mV | 50 mA |

2 | 14.2 – 28.3 nm | 1.5 V/m | 0.7 V/m | 0.8 V/m | 0.3 V/m | 0.2 V/m | 80 dBμV | 10 mV | 20 mA |

3 | 10 – 14.2 nm | 1 V/m | 0.5 V/m | 0.7 V/m | 0.2 V/m | 0.1 V/m | 70 dBμV | 3.16 mV | 10 mA |

4 | 7.7 – 10 nm | 0.7 V/m | 0.5 V/m | 0.5 V/m | 0.2 V/m | 0.1 V/m | 70 dBμV | 3.16 mV | 5 mA |

ESD Auditor Training Program provides ESD Basics, ANSI/ESD S20.20 program and TR53 compliance verification procedures with hands-on practices. This training program contains 2 full days training and 1 day hands-on certification exams.

Attendees will understand technical terminology, ESD basics theory, ESD models, measurement theory, control methodology, material testing methods and ionization techniques which are all part of ESD control programs in day 1.

Hands-on training with standard equipment during the training program for each item in TR53 document. Each session is built for practical learning with sample set up and fully prepared most of the items in day 2.

Day 1 | Day 2 | Day 3 |

Technical Terminologies | ESD control program | Hands-on Exams : Individually for 20 minutes |

Frequently using Engineering Units and Expression | TR53 Measurement Instrument | |

Charge Generation | Calibration vs. Verification | |

ESD Models | Hands-on Measurement

| |

Control Strategy | Q&A | |

Measurements and Testing Procedures | ||

Ionization | ||

Q&A |